Donwell Company: Teflon™ industrial coatings Applicator, Solid Film Lube / Dry Film Lube Applicator

Donwell is a Licensed Industrial Applicator of Teflon™ industrial coatings

Functional Coating Summary

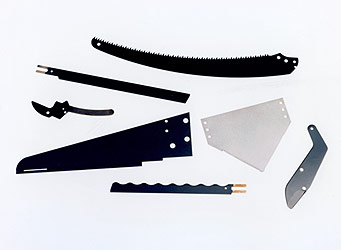

Teflon™ and Xylan® coated blades |

Coating for heat resistance sealing and unique electrical properties |

Teflon™ "S" 958G-203

Best thin film abrasion resistance with good non-stick using FEP and polyamide-imide as reinforcement – 500°F service

Teflon™ "S" 958G-303

Similar to 958-203 but better lubricity due to more PTFE – 500°F service

Teflon™ "S" 954G-303

Capable of thicker films; epoxy reinforcement with FEP for non-stick; good lubricity and corrosion resistance – 300°F service

Henkel Emralon 333

Best thin film abrasion resistance and lubricity with PTFE and polyamide-imide as reinforcement – 500°F service

Ceramic Reinforced Teflon™

Industrial black metallic coating using PFA as very durable but nearly pure topcoat for non-stick, abrasion resistance, and for lubricity; great non-stick – 500°F service

Whitford Xylan 8840

Hard resin base for reinforcement with a high content of FEP for great non-stick – 450°F service

Teflon™ PFA

Pure clear topcoat over primer for great lubricity, non-stick, and abrasion resistance for a pure fluoropolymer; excellent corrosion resistance – 500°F service

Teflon™ FEP

Pure clear topcoat over primer best non-stick ever; low abrasion resistance; best corrosion resistance – low temperature resistance – 300°F service

Teflon™ 420G-104

Hard resin base with PTFE great lubricity; good abrasion resistance – 500°F service

Everlube Products

Ultra high bearing pressure lubricant; up to 150,000 PSI; MOS2 and/or graphite thermoset reinforcement – up to 1000°F service

PTFE

Capable of thicker films for cold-flow sealing purposes; best lubricity in thin films; low abrasion resistance – 500°F service

Dry Film RA

Ultra-thin {.0002"} PTFE; best lubricity; low abrasion resistance; immersion process capable for I.D. coatings; low cost – 500°F service